What is In-Situ Recovery (ISR)?

ISR is an environmentally-friendly process by which copper can be extracted from the ground with minimal disturbance to the surface environment. ISR mining has a long history, starting with uranium mining in the 1960s. Arizona also has a positive track record for ISR permitting. For example, the San Manuel copper mine, owned by BHP Billiton, was a successful operation that integrated ISR methods with open pit and underground mining and produced approximately 3.25 billion pounds of copper in 14 years of production. Two additional projects owned by BHP Billiton, Pinot Valley and the Miami Unit, also used ISR to extract copper (combined with SX-EW in the case of the Miami Unit).

Advantages to In-Situ Recovery Mining:

- Lower capital and operating costs

- No waste or ore moved

- No creation of open holes, waste dumps, leach pads or tailings

- Minimal visual disturbance

- Minimal noise, dust and greenhouse gas impact

- Fewer permits are required compared to other mining processes

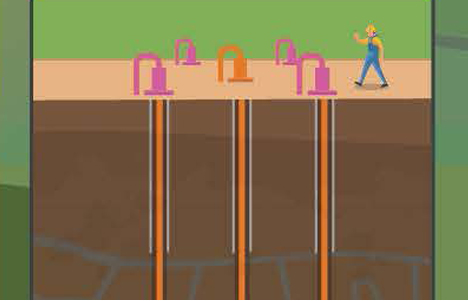

How does ISR work?

In-situ recovery (ISR) is a non-invasive mining method whereby boreholes or “delivery wells” are drilled into an ore-body, through which a dilute solution is pumped to dissolve the target minerals or metals. The solution moves through the rock in a controlled manner to nearby recovery wells, where it is pumped back to the surface for processing. Differential pumping rates or natural impermeable barriers are used to control the movement of the solution through the rock. This, combined with well field design, prevent any solution from exiting the mine area. The pumping action of the recovery wells ensures all of the pregnant solution is collected from the delievery well. In ISR mining of copper oxide ores, the dissolving solution is usually weak sulfuric acid, the same acid used in open pit and dump or heap leach operations around the world. In effect, the bore holes or wells become the “mine access” and the leach pad is “left underground”. Processing is usually done by chemical precipitation or solvent extraction electrowinning (SX-EW).

Is ISR safe?

The wells used for injection and recovery are all closely monitored and arranged to ensure the containment and control of the mining solution. Closure of a copper ISR operation usually involves cessation of solution injection with continued, moderate, recovery well pumping that flushes any remaining solution from the rocks. Wells can then be filled with cement so that the land can be returned to its pre-mining state.

The United States has very strict guidelines for ensuring the safety and health of its citizens. The Department of Environmental Quality ensures that during ISR mining no solution escapes from the mining area. Following ISR mining, a company must return groundwater to background chemical levels (levels prior to when mining began).

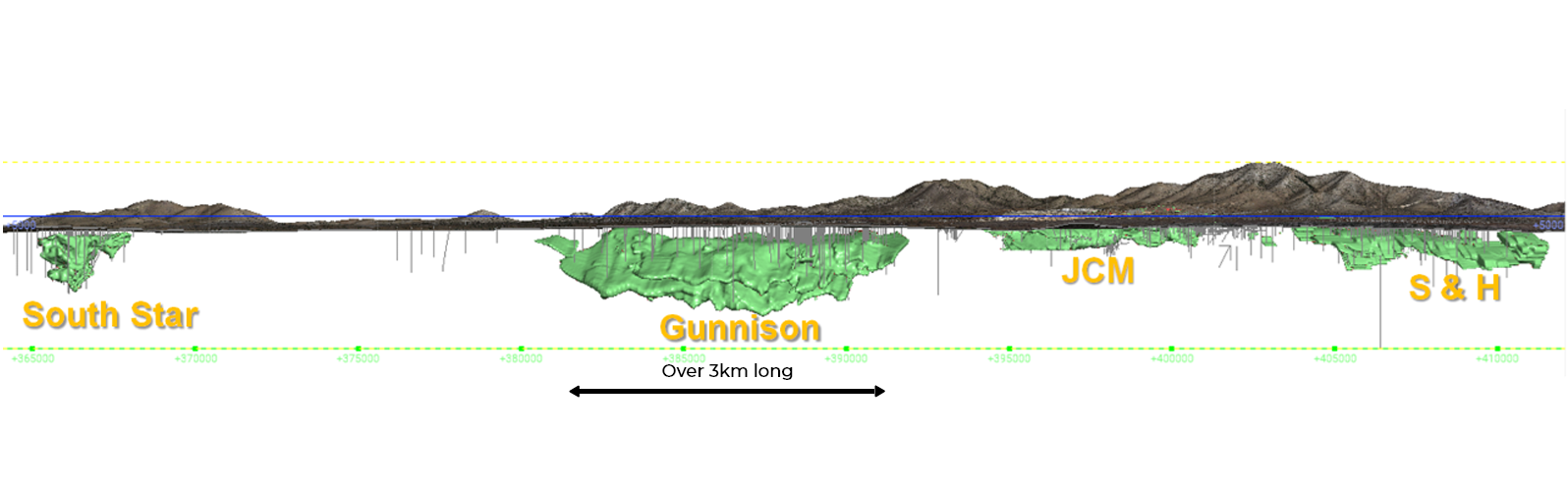

What are the limitations of ISR?

The optimal conditions to use In-Situ Recovery for copper mining follow a few guidelines. Firstly, the host rock needs to be fractured enough to allow for the solution to permeate through and dissolve the copper resource. The more fractured the rock, the more surface area there will be for the copper to be dissolved. Secondly, the copper resource must be below the water table. Without the mentioned guidelines, the in-situ process will be ineffective or will not comply with standards set out for mining procedures.