February 14, 2013

Excelsior Mining Corp. (TSX-V: MIN) (Frankfurt: 3XS) (OTCQX: EXMGF) ("Excelsior" or the “Company”) is pleased to announce results from recent metallurgical tests on copper oxide mineralization from its North Star deposit, part of Excelsior’s Gunnison Copper project, located in southeastern Arizona.

Two types of tests were performed.

- Submerged leach tests. These modified column-leach tests generated recoveries of acid soluble copper in the range of 82% to 95% over periods from 49 to 99 days. Higher recoveries were achieved with higher acid concentrations or longer leach times.

- Acid consumption tests. These tests were designed to evaluate relative acid consumption from in-situ leaching versus standard metallurgical testing. The tests demonstrated that standard metallurgical testing (including the submerged leach tests) significantly over-estimates acid consumption compared to values expected under in-situ operating conditions.

“We are extremely pleased with the high recovery and low acid consumption from these recent metallurgical tests,” stated Stephen Twyerould, President and CEO of Excelsior. “We are looking forward to the positive impact of combining these results with the recent favourable hydrological results as Excelsior continues to complete the work required to prepare a pre-feasibility study.”

Acid consumption test details

Due to the nature of the copper oxide mineralization at North Star, combined with standard metallurgical testing procedures on drill core, more of the un-mineralized rock known as “gangue” is inadvertently exposed to the acid solution than would be expected during normal in-situ mining conditions. This overexposure results in inflated acid consumption rates from metallurgical testing compared to those expected during actual in-situ operational conditions.

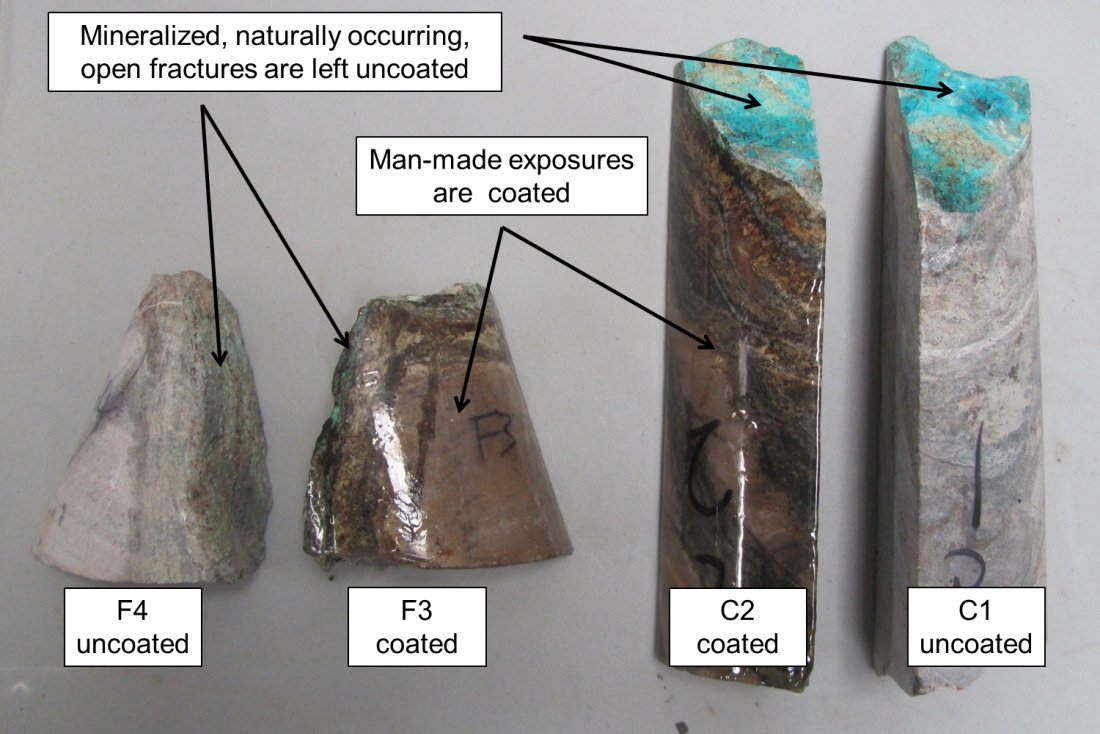

To demonstrate this, two pairs of identical samples were collected from the Martin formation within the North Star deposit. Man-made exposures on one half of each pair were coated with an impermeable acid resistant epoxy (see Figure 1), leaving the naturally occurring, mineralized fractures, uncoated. In this way, the leach solution could only react with the naturally occurring fractures in the coated sample, just as it would during real-world in-situ leaching conditions. As a control, the other half of the pair was left uncoated, as would occur in standard metallurgical testing (including the submerged leach tests described below). All samples were then submerged in a dilute acid solution and the amount of copper leached and acid consumed were monitored.

Figure 1. Photograph showing epoxy and non-epoxy coated samples prior to testing.

After 72 days submerged in dilute sulfuric acid, the acid consumption was up to 82% less for the epoxy coated samples (simulating in-situ conditions), compared to the uncoated samples (see Table 1 below). While the testing is continuing, these results clearly show the inadvertent overestimation of acid consumption that occurs during standard metallurgical testing as compared to expected operational conditions.

Table 1. Results of comparative acid consumption tests.

|

Sample

|

Epoxy

|

Acid Consumption*

lbs/lb Cu

|

% change in acid

consumption

|

|

C1

|

Uncoated

|

11.30

|

|

|

C2

|

Coated

|

2.07

|

-82%

|

|

F4

|

Uncoated

|

23.93

|

|

|

F3

|

Coated

|

13.99

|

-42%

|

* Acid consumption in pounds of acid consumed per pound of copper recovered

The acid consumption tests are being conducted by independent consultant Mountain States R&D International, Inc. of Tucson, Arizona under the supervision of Dr. Ronald J. Roman of Leach, Inc., Tucson, Arizona. Dr. Roman has reviewed and approved the technical information disclosed above in this news release and is an independent consultant who is a Qualified Person (QP) as defined by National Instrument (NI) 43-101. Dr. Roman has verified the data underlying the test results by designing the test procedure, supervising the test work, obtaining all the analytical data over the life of the experiment and performing the calculations presented above.

Submerged leach tests details

Submerged leach testing employs a protocol similar to column leach testing but modified to more closely reflect conditions during in-situ leaching. These tests were designed to be repeatable, and to evaluate the response of mineralization to in-situ leaching at different flow rates and acid concentrations.

To date, five of the 13 tests have been completed and the results are presented in Table 2 below. The remaining eight tests are still under active leaching and are expected to conclude in the next 30 to 60 days. The five tests completed are from the Lower Abrigo rock formation.

Higher acid concentrations (e.g. column 9) and/or longer leach times (e.g. column 13) generated higher recoveries, indicating 100% acid soluble copper is recoverable given sufficient time, acid concentration and economics.

Table 2. Results from submerged leach tests on the Lower Abrigo formation.

|

Column

|

Head Grade1 %Cu

|

Flow

rate2, lph/m2

|

Acid

content3, gpl acid

|

Days

leached4

|

Recovery, %

|

Acid

Consumption5 lbs/lbs |

|

|

Cu total

|

Cu acid soluble

|

Cu acid soluble

|

|||||

|

9

|

0.31

|

0.23

|

22

|

15

|

61

|

95

|

19

|

|

10

|

0.33

|

0.26

|

37

|

10

|

49

|

85

|

12.6

|

|

11

|

0.28

|

0.21

|

22

|

10

|

61

|

87

|

17.3

|

|

12

|

0.29

|

0.21

|

22

|

5

|

61

|

82

|

9.7

|

|

13

|

0.28

|

0.20

|

11

|

5

|

99

|

92

|

12.6

|

- Calculated head grade

- Flow rate in litres per hour per cross-sectional square metre

- Acid concentration in grams per litre of free acid

- Days leached includes one or two days of post leach rinsing but does not include the extended post leach rinsing period

- Acid consumption in pounds of acid consumed per pound of copper recovered

The submerged leach tests are being conducted by independent laboratory SGS Metcon of Tucson, Arizona under the supervision of Dr. Ronald J. Roman, an independent consultant who is a Qualified Person as defined by NI 43-101. Dr. Roman has reviewed and approved the technical information disclosed in this news release. Dr. Roman has verified the data underlying the test results by designing the test procedure, supervising the test work, obtaining all the analytical data over the life of the experiment and performing the calculations presented above.

More detailed information concerning these metallurgical tests can be found on the Excelsior website at:http://excelsiormining.com/index.php/projects.

Project Summary

The Gunnison Copper Project is located in a remote section of Cochise County in southeastern Arizona. The focus of the project is the North Star deposit, which currently has a total Indicated mineral resource of 3.21 billion pounds of oxide copper (511 M tons at 0.31%) and an Inferred mineral resource of 0.88 billion pounds of oxide copper (159 M tons at 0.28%). This oxide mineral resource has the potential to be mined using in-situ recovery methods. Mineral resources which are not mineral reserves do not have demonstrated economic viability.

About Excelsior

Excelsior is an exploration company with a copper project located within the Copper Porphyry Belt of Arizona. The Gunnison Copper Project is located close to the required infrastructure and its oxide copper resource has the potential to be mined using in-situ recovery methods. The Excelsior team consists of experienced professionals with proven track records of advancing projects towards production.

Excelsior’s exploration work on the Gunnison Property is supervised by Dr. Stephen Twyerould, Fellow of AUSIMM, President and CEO of Excelsior, and a Qualified Person as defined by NI 43-101. Dr. Twyerould has reviewed and approved the technical information disclosed in the “Project Summary” and “About Excelsior” sections of this news release.

Further details about Excelsior can be found at: http://www.excelsiormining.com. Further information about the Gunnison Copper Project can be found in the technical report filed on SEDAR at www.sedar.com entitled: “Gunnison Copper Project Preliminary Economic Assessment, NI 43-101 Technical Report” dated November 18, 2011.

ON BEHALF OF THE EXCELSIOR BOARD

"Stephen Twyerould"

President & CEO

For further information regarding this press release, please contact:

Excelsior Mining Corp.

Concord Place, Suite 300, 2999 North 44th Street, Phoenix, AZ, 85018.

JJ Jennex, Vice President, Corporate Affairs

T: 604-681-8030 x240

E: This email address is being protected from spambots. You need JavaScript enabled to view it.

www.excelsiormining.com

Cautionary Note Regarding Forward-Looking Information

This news release contains "forward-looking information" concerning anticipated developments and events that may occur in the future. Forward looking information contained in this news release includes, but is not limited to, statements with respect to: (i) the estimation of inferred and indicated mineral resources; (ii) the future implications of the metallurgical test results; (iii) production from the Gunnison Project; (iv) the completion of a pre-feasibility study; (v) expected acid consumption rates and; (vi) the ability to mine Gunnison using in-situ recovery mining techniques are forward-looking statements.

In certain cases, forward-looking information can be identified by the use of words such as "plans", "expects" or "does not expect", "is expected", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur" or "be achieved" suggesting future outcomes, or other expectations, beliefs, plans, objectives, assumptions, intentions or statements about future events or performance. Forward-looking information contained in this news release is based on certain factors and assumptions regarding, among other things, the estimation of mineral resources, the realization of resource estimates, copper and other metal prices, the timing and amount of future exploration and development expenditures, the estimation of initial and sustaining capital requirements, the estimation of labour and operating costs, the availability of necessary financing and materials to continue to explore and develop the Gunnison Project in the short and long-term, the progress of exploration and development activities, the receipt of necessary regulatory approvals, the completion of the environmental assessment process, the estimation of insurance coverage, and assumptions with respect to currency fluctuations, environmental risks, title disputes or claims, and other similar matters. While the Company considers these assumptions to be reasonable based on information currently available to it, they may prove to be incorrect.

Forward looking information involves known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of the Company to be materially different from any future results, performance or achievements expressed or implied by the forward-looking information. Such factors include risks inherent in the exploration and development of mineral deposits, including risks relating to changes in project parameters as plans continue to be redefined including the possibility that mining operations may not commence at the Gunnison Project, risks relating to variations in mineral resources, grade or recovery rates resulting from current exploration and development activities, risks relating to the ability to access infrastructure, risks relating to changes in copper and other commodity prices and the worldwide demand for and supply of copper and related products, risks related to increased competition in the market for copper and related products and in the mining industry generally, risks related to current global financial conditions, uncertainties inherent in the estimation of mineral resources, access and supply risks, reliance on key personnel, operational risks inherent in the conduct of mining activities, including the risk of accidents, labour disputes, increases in capital and operating costs and the risk of delays or increased costs that might be encountered during the development process, regulatory risks, including risks relating to the acquisition of the necessary licenses and permits, financing, capitalization and liquidity risks, including the risk that the financing necessary to fund the exploration and development activities at the Gunnison Project may not be available on satisfactory terms, or at all, risks related to disputes concerning property titles and interest, environmental risks and the additional risks identified in the “Risk Factors” section of the Company’s Annual Information Form for the most recently completed financial year or other reports and filings with applicable Canadian securities regulations.

Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in forward-looking information, there may be other factors that cause actions, events or results not to be as anticipated, estimated or intended. Accordingly, readers should not place undue reliance on forward-looking information. The forward-looking information is made as of the date of this news release. Except as required by applicable securities laws, the Company does not undertake any obligation to publicly update or revise any forward-looking information.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release, and no securities regulatory authority has either approved or disapproved of the contents of this release.