Excelsior Mining Corp. (TSX-V: MIN) (Frankfurt: 3XS) (OTCQX: EXMGF) ("Excelsior" or the “Company”) is pleased to announce final metallurgical results for the Gunnison Copper Project in Arizona. These comprehensive results will be incorporated into a full Feasibility Study scheduled for completion in 2016.

The final results from ten fracture simulation box tests can be found in Table 1 below. Results indicate that copper leaches rapidly and relatively uniformly across all rock types.

Forward modelling of the recovery time curves and acid consumption curves (see graphs) indicate average acid consumption at 100% acid soluble copper recovery (approximately 70% total copper recovery), would be in the range of 8 to 10 pounds of acid consumed for every pound of copper cathode produced. This is consistent with the previously reported Prefeasibility Study that used approximately 8.1 pounds of acid consumed for every pound of copper cathode produced.

Commenting on these results, Stephen Twyerould, President and C.E.O. said, “These results are completely in-line with the results from our 2014 Prefeasibility Study and fully support the industry leading economics that define our Gunnison Copper Project. We remain excited by the rapid advancement of the Project and the use of this new data in our upcoming Feasibility Study.”

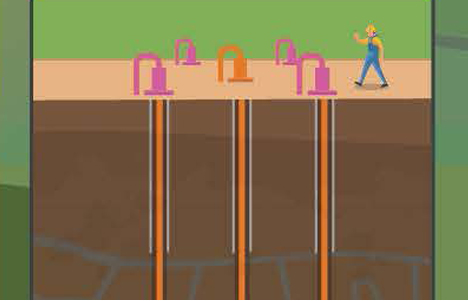

The fracture simulation leach tests were designed to simulate the leaching of copper from a fracture surface as would occur during in-situ recovery operations at the Gunnison Copper Project. Natural, mineralized, fracture surfaces were taken from drill core representing the major rock and mineralization types found in the deposit. Samples were then embedded in acid resistant epoxy such that all un-natural surfaces of the core were covered by epoxy and the natural, mineralized, fracture surfaces were left exposed to the leach solution. The samples were placed in an approximately 9 foot long by 10 inch wide clear Perspex box with the un-coated mineralized fracture surfaces facing upwards, and the rest of the sample surrounded by epoxy, thereby restricting the leaching process to the fracture surfaces. A clear Perspex lid was placed on top of each box with minimal void space between the lid and the fracture surface. Mature raffinate, at 15 grams per litre acid concentration, was delivered at one end of the box, fully saturating the core, and moving across the fracture surface in a controlled manner, thereby producing copper-rich leach solution that was collected and sampled at the other end of the box. For further information, please see the Company’s previous news release dated May 20, 2015 – “Excelsior’s Preliminary Metallurgical Tests Fully Consistent with Prefeasibility Results”

Table 1: Final results from fracture simulation leach testing.

| Ore | Core Tray | At 116 days** | At 166 to 197 days*** | ||

| Recovery* % | Acid Consumption (lbs/lb Cu) |

Recovery* % |

Acid Consumption (lbs/lb Cu) | ||

| Lower Abrigo | 1 | 73.1 | 5.7 | 83.1 | 6.2 |

| 10 | 72.7 | 5.2 | |||

| Middle Abrigo | 6 | 63.3 | 5.8 | ||

| 9 | 63.8 | 7.0 | |||

| Upper Abrigo | 2 | 71.8 | 3.6 | 82.7 | 4.4 |

| 5 | 70.7 | 9.9 | |||

| Martin | 3 | 59.8 | 5.3 | 73.7 | 6.0 |

| 4 | 65.1 | 13.5 | |||

| 7 | 66.3 | 9.9 | |||

| 8 | 62.7 | 3.6 | |||

|

* The recovery percentage is expressed as the percentage of leachable copper, which includes typical acid soluble minerals as well as slow leaching oxides and transitional sulfides.

** Leaching of core trays 4 to 10 was terminated at 116 days after sufficient data had been obtained.

*** Leaching of core trays 1, 2 and 3 was terminated at 199, 166 and 197 days respectively.

|

|||||

These core tray results, along with previous study results, will be used in future numerical modelling designed to simulate in-situ recovery and further evaluate operational copper recovery and acid consumption under different well field and operational conditions. The metallurgical recovery and acid consumption described in this press release do not include estimates of well field efficiency (“sweep efficiency”) and other operational conditions, which are expected to reduce total mining recovery to approximately 45% to 50% of total copper.

Additionally, 19 column leach tests were completed in order to investigate geological variability. Copper recoveries were quick and overall results remained consistentwith previous column leach tests. Because the goal of these tests was to leach only long enough to establish trends, all of the column leach tests ran for a very short duration of approximately 60 days. This deliberately short time period resulted in observed acid soluble recoveries of between 60% and 80%. Had the leach cycle been longer, 100% recovery of acid soluble copper could be expected. Because column leach testing requires the sample rock to be crushed, these tests are not appropriate for providing data on acid consumption.

Of greatest significance, substantial copper recoveries were recorded from slow leaching oxides and transitional sulphides that do not report to the acid soluble assay. This “insoluble copper” has the potential to improve upon total recoveries during commercial production.

The column leach test results can be viewed here – LINK TO TABLE. Columns 6B and 3 are not included because residual assays have not yet been returned.

Metallurgical testing is being conducted by the independent laboratory, "Mineral Advisory Group, Research & Development, LLC", ("MAG R&D") of Tucson, Arizona under the supervision of Dr. Ronald J. Roman, an independent consultant who is a Qualified Person as defined by National Instrument 43-101. Dr. Roman has reviewed and approved the technical information disclosed in this news release. Dr. Roman has verified the data underlying the test results by designing the test procedure, supervising the test work, obtaining all the analytical data over the life of the experiment and performing the calculations presented above.

Excelsior is a mineral exploration and development company that is advancing the Gunnison Copper Project. The Excelsior management team consists of experienced professionals with proven track records of advancing mining projects into production. Further information about the Gunnison Copper Project can be found in the technical report filed on SEDAR at www.sedar.com entitled: “Gunnison Copper Project, NI 43-101 Technical Report, Prefeasibility Study” dated February 14, 2014.

For more information on Excelsior, please visit our website at www.excelsiormining.com.

"Mark J. Morabito"

Executive Chairman

For further information regarding this press release please contact:

Cautionary Note Regarding Forward-Looking Information

This news release contains "forward-looking information" concerning anticipated developments and events that may occur in the future. Forward looking information contained in this news release includes, but is not limited to, statements with respect to (i) acid consumption and copper recoveries; (ii) the preparation of a feasibility study; and (iii) the advancement of the Gunnison Project.

Such forward-looking information can be identified by the use of the word “will”. Forward-looking information contained in this news release is based on certain factors and assumptions regarding, among other things, the estimation of mineral resources and mineral reserves, the realization of resource and reserve estimates, copper and other metal prices, the timing and amount of future exploration and development expenditures, the estimation of initial and sustaining capital requirements, future recovery assumptions, the estimation of labour and operating costs, the availability of necessary financing and materials to continue to explore and develop the Gunnison Project in the short and long-term, the progress of exploration and development activities, the receipt of necessary regulatory approvals, the completion of the permitting process, the estimation of insurance coverage, and assumptions with respect to currency fluctuations, environmental risks, title disputes or claims, and other similar matters. While the Company considers these assumptions to be reasonable based on information currently available to it, they may prove to be incorrect.

Forward looking information involves known and unknown risks, uncertainties and other factors which may cause the actual results, performance or achievements of the Company to be materially different from any future results, performance or achievements expressed or implied by the forward-looking information. Such factors include risks inherent in the exploration and development of mineral deposits, including risks relating to changes in project parameters as plans continue to be redefined including the possibility that mining operations may not commence at the Gunnison Project, risks relating to variations in mineral resources and reserves, grade or recovery rates resulting from current exploration and development activities, risks relating to the ability to access infrastructure, risks relating to changes in copper and other commodity prices and the worldwide demand for and supply of copper and related products, risks related to increased competition in the market for copper and related products and in the mining industry generally, risks related to current global financial conditions, uncertainties inherent in the estimation of mineral resources, access and supply risks, reliance on key personnel, operational risks inherent in the conduct of mining activities, including the risk of accidents, labour disputes, increases in capital and operating costs and the risk of delays or increased costs that might be encountered during the development process, regulatory risks, including risks relating to the acquisition of the necessary licenses and permits, financing, capitalization and liquidity risks, including the risk that the financing necessary to fund the exploration and development activities at the Gunnison Project may not be available on satisfactory terms, or at all, risks related to disputes concerning property titles and interest, environmental risks and the additional risks identified in the “Risk Factors” section of the Company’s reports and filings with applicable Canadian securities regulators.

Although the Company has attempted to identify important factors that could cause actual actions, events or results to differ materially from those described in forward-looking information, there may be other factors that cause actions, events or results not to be as anticipated, estimated or intended. Accordingly, readers should not place undue reliance on forward-looking information. The forward-looking information is made as of the date of this news release. Except as required by applicable securities laws, the Company does not undertake any obligation to publicly update or revise any forward-looking information.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release, and no securities regulatory authority has either approved or disapproved of the contents of this release.